Custom Beamsplitter Supplier and Manufacturer

While beamsplitter is a term that includes many different functions and types of optics, at their core, beamsplitters divide a single beam into two different optical paths. This split can be based on intensity (partial reflectors), wavelength (color filters), or polarization (polarizers). Regardless of their function, they come in two basic geometries: plates and cubes. Each has its own advantages/disadvantages in a particular application. PFG produces custom beamsplitter plates and cubes in the UV, visible, and MWIR for a wide variety of different industries.Optical Beamsplitter Selection

PFG offers different types of beam splitters such as an extensive variety of plate beamsplitters from UV to MWIR in a wide selection of sizes, glass types, surface quality, and a polarization state. We use optical beamsplitters with unpolarized light sources, such as polychromatic. A light beam splitter is commonly used in applications where polarization state is not important. Ranging from neutral density to dichroic beam splitter coating technologies to bandpass, including both polarizing and non-polarizing beamsplitter, we can customize them. These beamsplitters can be applied to right-angle prisms, wedges, Penta, or rhomboids and may be optically cemented or chemically contacted for improved laser damage threshold. Dichroic beamsplitters can split incident light by wavelength. These range from laser beam combiners we design for laser wavelengths to broadband cols and hot mirrors for splitting visible and infrared light.

Plate Beam Splitters

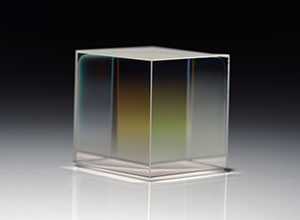

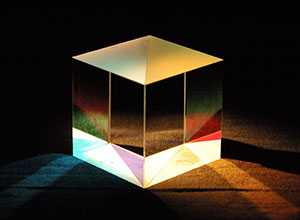

Cube Beam Splitter

Polarizers

Laser Line Beam Splitter

Partial Reflectors

Color Filters

Partial Reflectors

Partial reflectors are designed to split a beam into two paths with different intensity levels. These reflectors can come in any splitting ratio (R/T), such as 95/5, 90/10, 80/20, and 50/50. The equal 50/50 beamsplitter is often used to split a beam into two beams of equal intensity.Color Filters

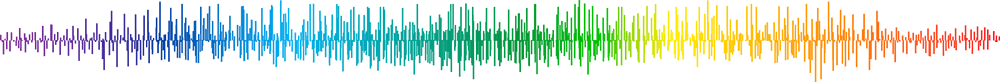

Color filters, despite their name, are not limited to visible color filtering. More generally, these beamsplitters are designed to split a common beam into different paths with different wavelength bands. They accomplish this by reflecting, or blocking, one or more wavelength ranges while transmitting others.Polarizer

A polarizer is a type of beamsplitter designed to split a randomly polarized light beam into its two polarization states. Most often, polarizers are designed to transmit p-polarized light and reflect s-polarized light. Polarizers must be designed to be used at an angle, usually either a 45-degree or 56-degree angle of incidence.Cube Beamsplitters

Because the polarization effects of a coating are enhanced when immersed inside glass, cube beamsplitters are useful for creating polarizing beamsplitters. Polarizers and broadband beamsplitters are much simpler and more cost-effective when done as a cube beamsplitter.Plate Beamsplitters

Plate beamsplitters have an advantage over cube beamsplitters due to their reduced size, weight, and complexity. Plate beamsplitters require light to traverse much less glass than cube beamsplitters and don’t require a cement layer, which influences the laser-induced damage threshold of the beamsplitter.CUSTOM BEAMSPLITTERS

Our sales and engineering team will review your optical drawing or custom specifications and provide an estimate. Typically, we offer:| Specification | Limit |

|---|---|

|

Size: |

3 to 400mm |

|

Surface roughness: |

15Ǻ with the ability to provide below 5Ǻ if requested |

|

Surface quality: |

60/40 standard down to 10/5 Laser Quality (scratch/dig) |

|

Diameter: |

±0.05mm down to ±0.010mm |

|

Center Thickness (CT): |

±0.1mm down to ±0.025mm |

|

Diameter: |

±0.05mm down to ±0.010mm |

|

Clear Aperture (CA): |

85% down to 0.5mm or more from the edge of the finished optic |

|

Lens Centering: |

0.01mm ETD or 1 arc-minute deviation; 0.003mm ETD or 10 arc-seconds deviation |

Optical Thin Film Coating Department Capabilities

- Specialize in producing custom coatings to meet customer specifications

- Electron Beam (E-Beam) and Ion-Assisted (IAD) coating process technologies

- Laser Line Coatings, Anti-Reflection, Highly Reflective, V-Coats, Broadband, Metallic, Polarizing, Non-Polarizing, Beamsplitters, Long-Pass Filters, and Short-Pass Filters

- Ultra-broadband AR’s available – covering visible and infrared (ex. 400nm – 2µm)

In-house environmental testing: adhesion test, abrasion test, thermal-humidity test, temperature influence test, and stress test Coating charts and witness samples are routinely supplier