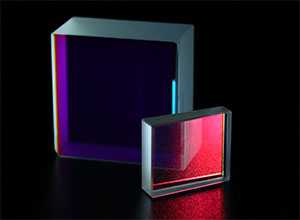

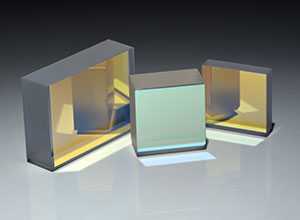

Polarizing Beam Splitter Cube and Plate Polarizers

At PFG Optics, we are dedicated to producing a range of polarization optics that meet the highest standards of precision and quality. We achieve this through the implementation of rigorous polishing and coating process parameters. Our product offerings include various polarization optics such as laser line polarizing cube beamsplitters, plate polarizers, and broadband thin film polarizers specifically designed for high-power laser systems. Whether you require high-energy laser line polarizers, infrared polarizing beam splitters, or custom-designed thin film polarizers tailored to your unique specifications, we possess the expertise and capabilities to provide comprehensive solutions. Our team of experienced professionals is committed to delivering products that meet or exceed the expectations of our valued customers.Types of Polarizers – Polarizer Selection

Our company, PFG Optics, specializes in producing customized thin film polarizer products that boast an unparalleled combination of characteristics, including a high extinction ratio, elevated damage threshold, minimal loss, superior mechanical durability, and an extended operational lifespan. Our range of polarizers encompasses a wide spectrum of wavelengths, including ultraviolet, visible, and mid-wave infrared, and boasts a diverse array of split ratios. In addition to our polarizer offerings, we manufacture an array of other optical components, including optical lenses, beam splitters, and optical prisms.

Adhering to best practices honed over decades of experience, we employ a variety of techniques, including tight centering, truncation, high included angles, and long radii, to ensure efficient and timely production. As a leading polarized optics manufacturer, we possess a vast library of test plates and employ state-of-the-art Zygo interferometers, all equipped with complete reference spheres for precise surface measurement.

UV Polarizer

High Energy Polarizers

Thin Film Cube Polarizers

Plate Polarizers

thin film laser polarizers

As a leading manufacturer of high-precision optical components, we specialize in the production of a diverse array of devices that generate or manipulate polarized light waves. Specifically, we offer a comprehensive range of polarizer optics, including dichroic sheet polarizers, cube or plate beamsplitters, lateral polarizers, professional circular polarizers, Glan laser polarizers, ultrafast polarizers, and more. These polarizers are based on one of the following four physical phenomena: reflection, selective absorption, scattering, and double refraction.- Reflection – as seen in the example of unpolarized sunlight impinging upon a horizontal glass plane, results in the polarization of light through impingement upon a reflective surface.

- Selective absorption – makes use of an anisotropic material that selectively absorbs one of the perpendicular electric fields while allowing the other to pass through undisturbed.

- Scattering – occurs as unpolarized light rays travel through space and pass through molecules, resulting in linear polarization along the electron vibration plane.

- Double refraction – the polarizer is composed of a material that exhibits two indices of refraction, and the polarization state and direction of the incoming light affect the refraction and resulting polarization state after passing through the material.

We offer infrared(IR) wire grid polarizers, glan Thompson polarizers, Glan Taylor UV polarizers, dichroic polarizers, birefringent polarizers, and more. Get laser line dichroic plate beamsplitters, photonic crystal polarizers polarizing beam splitters, four ideal linear sheet polarizers, UV linear dichroic polarizer glass, and more. What is the difference between linear and circular polarizers? A linear polarizer is more effective than a circular one. They are also less expensive. If you have questions like how wire grid polarizers work or how to design birefringent polarizers, talk to us! Precision right-angle prisms are ideal to deviate a light path by 90° or 180°. We have highly efficient and broadband optical polarizers based on dielectric nanowires. Laser splitter cube plate beamsplitters feature different sizes and materials. Our team also supplies Malus Law multiple polarizers for digital cameras and single crystals for polarizing prisms.

uses of optical polarizers

Our company is committed to producing the highest quality optical polarizers by utilizing cutting-edge technology and rigorous quality control protocols. - Polarization-Based Imaging: Polarizers are used in cameras and other imaging equipment to control the polarization of light, which can be used to reduce glare and improve image contrast.

- Optical Communications: Polarizers are used in optical fiber communication systems to improve the signal-to-noise ratio and reduce crosstalk.

- Display Technology: Polarizers are used in LCD and OLED displays to control the polarization of light and improve the visibility of the display.

- Industrial Sensing: Polarizers are used in industrial sensors to detect the position, orientation, or movement of objects.

- Medical Equipment: Polarizers are used in medical equipment such as endoscopes and microscopes to improve image contrast and reduce glare.

- Spectroscopy: Polarizers are used in spectroscopy to analyze the properties of light, such as its wavelength and intensity.

- Metrology: Polarizers are used in metrology to measure properties such as the birefringence and dichroism of materials.

- Laser Systems: Polarizers are used in laser systems to control the polarization of laser beams, which is important for many laser applications such as laser cutting and welding, laser printing, and laser-based medical treatments.

- Solar Energy: Polarizers are used in solar energy systems to improve the efficiency of solar cells by controlling the polarization of light.

- Military and Aviation: Polarizers are used in military and aviation equipment to improve visibility and reduce glare, such as in helmet-mounted displays and night vision goggles.

What is the difference between linear and circular polarizers? Linear polarizers are used to block or transmit light with a specific polarization state, while circular polarizers use a combination of linear polarizing and quarter-wave retardation films to create a circular polarization effect and maintain a constant polarization state regardless of the orientation of the filter.

Order Polarizer Optics Today

A polarization optic is capable of selecting or changing specific polarizations. We can provide a diverse portfolio of polarizing cube beamsplitters, waveplates, and linear polarizers that operate over IR, UV, and visible spectral ranges. Quarter-wave and half-wave plate polarizers can come in achromatic, multiple-order, or zero-order versions. Thin-film polarizers can be utilized in high-energy Nd: YAG applications, as well as Ultrafast lasers and Ultrashort pulse, uses. Reach out to us for your optical polarizer needs.

Polarizing Filters

Linear polarizing filters increase color and contrast. The reflected light is a glare that also washes out color in imaging systems. Moreover, a circular polarizer filter can be used on-camera filters with a metering device also found on the CPL auto focus SLR’s camera lens. How are optical polarizers made? The best circular polarizer filter review corrects this problem producing polaroid color saturation, deep polarizing effect, or extensive blue skies. Plastics in non-metallic surfaces become birefringent when under stress almost like a wave retarder. From substrate preparation to optical coating, and product packaging thin film polarizer manufacturers apply our state-of-the-art expertise to both stock and custom polarization optics. Our variety of linear polarizers includes Polaror dichroic glass, laminated sheets, Calcite crystal types, and laminated polymer films. We also offer low-angle prisms, broadband non-polarizing beamsplitter cubes, broadband polarizing plate beamsplitter, brewster-type thin film polarizers, film wire grid polarizers, and more.

Polarization of Light

The polarization of light, both manipulating it and understanding it, is absolutely critical for optical uses. Often we see optical designs ignoring its polarization, instead of paying attention only to the intensity and wavelength. Polarization is an essential aspect that can have an effect on optical systems that are not even specifically measuring it. It can affect many things, such as preventing unwanted back reflections, altering filter cut-off wavelengths, and even changing the focus of laser beams. Metrology applications benefit from light polarization as well, through pharmaceutical ingredient analysis, biological microscopy, and stress analysis of materials like glass or plastic. Materials can absorb varying degrees of different polarizations, which is a critical aspect of 3D movies, glare-reduction eyewear, and LCD screens.

Does laser contain unpolarized light waves? Birefringent polarizers work to separate an incident beam in two beams. PFG provides wire grid polarizers, IR & dichroic polarizers, neutral density filters, circular polarizer films, and more. Get more info on precision linear polarizer intensity, polarized light filters, linear vs circular polarizers, Brewster’s angle, or how to design wide-angle birefringent polarizers!

Circular vs linear polarizer

The main difference in X-ray absorption between the two types of the plane of incidence polarization is called dichroism. Polarization state changes in absorption meaning the difference in the color of substances in the visible circularly polarized light through linear polarizer intensity region. The direction contains the degree of polarization modules that rely on the angle of incidence and the refraction index of the surface. We offer a wide range of waveplates, as well as some polarization rotators and other new products.

Review our standard and best tolerances. However, if these don’t perfectly fit your needs, please reach out to us so we can discuss what we can do for you.