What Are Conductive Coatings?

What Are Conductive Coatings?

In advanced opto-electronic systems, conductive thin-film coatings provide a unique combination of transparency and conductivity, making them essential in applications ranging from touchscreens and displays to electro-optical devices and electromagnetic interference (EMI) shielding. The most widely used materials for this purpose are a class of Transparent Conductive Oxides (TCO), the most common of which is Indium Tin Oxide (ITO) due to its ability to allow visible light to pass through while providing relatively low electrical sheet resistance. Another common solution is a patterned metallic grid, usually of a gold or silver metallic layer created with a lithographic process.

Applications of Conductive Coatings

1. EMI Shielding

Glass optics effectively “break” the Faraday cage of an opto-electronic system, exposing the internal electronics to EMI damage. Conductive coatings solve this problem by acting as transparent shielding layer, rejecting EMI while preserving optical transparency, making them critical in many defense, aerospace, and medical imaging systems. In this configuration, a low sheet resistance film with a low impedance path to ground is desired.

2. Heated Optics & Anti-Fog Solutions

Conductive coatings can also be used in de-icing and anti-fog applications. By applying an electrical current, the coating generates heat, preventing condensation or ice buildup on optical surfaces, such as aircraft windows, automotive cameras, and outdoor sensor systems. In contrast with EMI shielding, a high sheet resistance film is desired, which provides resistive heating across the optical surface.

3. Touchscreens & Displays

Smartphones, tablets, and interactive displays rely on conductive coatings to enable touch functionality. The conductive layer detects touch inputs while ensuring high light transmission for clear visuals.

Design Considerations

Usable wavelengths

Transparent conductive oxides tend to be very transparent in the visible spectrum (400-700nm), especially when paired with an anti-reflection (AR) coating. In visible spectra, TCO absorptive losses in the 1-5% range are typical, depending on the sheet resistance required.

However, in longer wavelengths, TCO coatings losses tend to become more significant. TCO coatings will begin reflecting (and absorbing) in the NIR region and beyond, especially >1um. This can be a problem depending on the application spectra. One typical solution to this is applying only very thin layers of material, limiting the total losses, at the cost of higher sheet resistance. For MWIR wavelengths and beyond, TCO coatings should be carefully considered alongside other solutions as losses will be extreme.

Electrical Connection

Connection from the system power bus to the film can be achieved a number of ways:

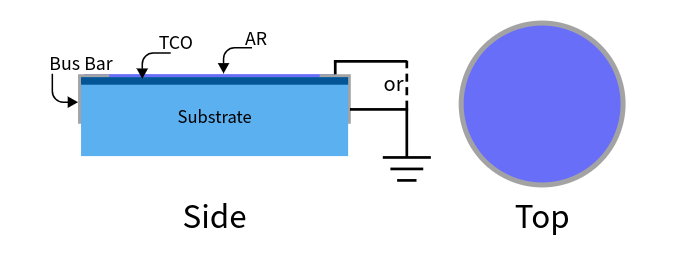

Metallic Bus Bars

A bus bar is a strip of conductive material (often silver) deposited around the perimeter of the coated optic. This provides a dedicated, low resistance contact area to attach electrical leads for near-uniform impedance. A bus bar improves electrical continuity and prevents localized high-resistance connections.

PFG generally recommends this method, and can create tooling to pattern bus bars in precise configurations. Bus bars can even be patterned to wrap around an optic’s edge, allowing connections from the optic’s face or diameter:

Contacts or Clips

Direct electrical contact to the conductive film with metal contacts or clips can be used to apply consistent pressure to the conductive conductive surface without requiring bus bars, adhesive, or soldering. This method yields a higher contact resistance than bus bars, and relatively high mechanical force must be used.

Conductive Epoxy

Conductive epoxy provides a secure, low-resistance bond between a wire and the conductive coating. Epoxy with silver fill (such as Master Bond EP3HTSDA-2) can provide low resistivity and high bond strength.

Custom Conductive Coatings at PFG Precision Optics

At PFG Precision Optics, we specialize in high-quality conductive coatings tailored to meet your specific needs.

Our coatings offer:

- High optical transmission and low scatter/haze for superior visibility ✅

- Precise sheet resistance control for sensitive applications✅

- Custom bus bar configurations for electronic integration✅

- AR coatings for minimizing TCO losses✅

Please contact PFG to discuss your next coating project! You can find more information on PFG’s coating capabilities here.