High-precision custom optics

Custom Optical Prisms

Made to fit stringent specifications for angle, flatness, transmitted wavefront, dimension, clear aperture, surface quality, and sharp rook. Current component optical precision manufacture capabilities include right angle, boresight, delta, porro, pechan, risley custom optics, optical dove prisms, pentaprisms, corner cubes, and rhomboids. High-quality optical components companies possess the technology, precision optics fabrication machine, ingenuity, and metrology to consistently deliver superior-performing prismatic objects. Our wholesale optical lens supplier also offers design and manufacturing services. Get in touch with one of the best custom optical lens manufacturers in the USA!

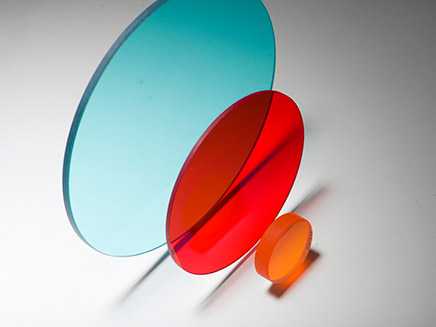

Optical flats

PFG Custom Precision Optics Manufacturers USA offers a variety of optical components including performance mirrors, windows, and wedges in a wide variety of shapes, sizes, and materials. Our high-precision optical components manufacturers technicians are comfortable working with 100+ glasses, fused silica, and optical crystal substrate materials. Selecting the optimal process technology and adhesion/blocking method allows us to produce optical flats and other fiber optics components quickly efficiently and to the most demanding specifications. So if you are looking for a company manufacturing optics products including flat optics, you are at the right place!

precision lenses

Custom lens optical manufacturing capabilities using all types of materials and processes. The best precision optic manufacturer selects top process technology to produce the required specifications. This precision optical lens manufacturing allows us to achieve the required optical performance desired from a given material such as optical components from fused silica. Our United States custom optics manufacturer best practices have been developed from decades-long experience to achieve timely and efficient production. While our precision optics manufacturers USA team specializes in custom lens manufacturer processes PFG also offers a wide range of services and optical precision components for optics. Our optic lens supplier offers a wide range of optical components from custom cylindrical lenses, surface high-quality optics USA, and precision optical lens manufacturers to broadband polarizing beamsplitter cubes. Optical lens suppliers can help with any custom laser optics manufacturing or dielectric thin film coatings!

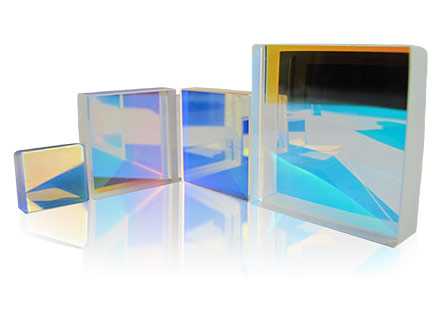

Optical Beamsplitters

Extensive selection of tight-tolerance plate and cube, typically polarizing beamsplitters from UV to MWIR. Industrial laser optics companies offer an extensive variety of plate and cemented beamsplitters from UV to MWIR in a wide selection of sizes and color filter glass types. We have different companies manufacturing optics products ranging from neutral density to dichroic to bandpass, including both polarizing and broadband non-polarizing beamsplitter cubes. PFG Precision Optical Manufacturing Group can customize these beamsplitters to meet your specific application. The applications of these beamsplitter products include right-angle prisms, wedge prisms, penta-prisms, or rhomboids and may be optically cemented or chemically contacted for improved laser damage threshold. So, for custom optical design engineering, get in touch with PFG, a leading precision optics company!

Custom Polarization Optics

Thin film cube or plate polarizers that deliver an impressive combination of qualities. PFG fiber optical manufacturer has stringent polishing and coating process parameters that ensure optimal polarizers. We can match extinction ratio, high damage threshold, low loss, optical quality control, excellent mechanical durability, and long operational lifetime. Our special optical glass manufacturer offers optical manufacturing services and different imaging solutions: laser optics, defense, research custom optics, precision optics, and so on. Manufactures custom optics capabilities include: ultraviolet, visible, and mid-wave IR wavelengths with many split ratios. Our compliant ITAR-registered manufacturer in the United States also has high-precision optics fabrication equipment to perform any task.

We offer custom optics manufacturing, rapid prototyping services, and quality optical service. So if you are looking for rapid prototyping manufacturing for high-quality optics reading glasses, that’s what we do. US optics quality control and iso optical surface quality measurement for many industries.

custom optical assemblies

PFG is an ITAR-registered and compliant manufacturer of custom optics solutions lasers has custom optical assemblies including military optical assemblies, electro-optical assemblies, thermal requirements for optical assemblies for life sciences industries, and more

US manufactures custom optics designs that have synthetic fused silica quartz glass optics, thin-film coatings, power laser mirrors for global life sciences industry companies, lenses laser mirrors for sale, and more. What are the different types of optical lenses for glasses? Special optical glass manufacturer makes filter glass for life sciences markets. Custom optical glass suppliers can describe the pros and cons of the best anti-reflective lens coating, as well as explain what constitutes a standard anti-reflective coating for vision. Contact us for any questions!