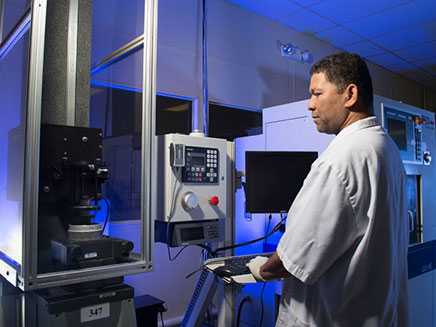

At PFG we have extensive equipment that allows us to produce a variety of high-precision optics our customers need. Our technicians use mills, grinders, spindle polishers, double-sided polishers; CNC mills, polishers, and edgers; MRF polishing, automated cleaning equipment, e-beam, and IAD coaters, spectrophotometers, and interferometers. While continually expanding and tightening the tolerances on our tooling, our engineers also focus on upgrading equipment and developing improvements to our existing processes. We attract, train, and develop a workforce that strives to expand our capability and operate our equipment with increased proficiency.

From the cementing of achromats to the alignment and mounting of optics in metal housings, we have the experience, process equipment, and metrology to complete your sub-assembly.

We believe that metrology equipment is equally as important as fabrication and coating equipment. Metrology is critical not only because it validates the finished specifications but also aids in our fabrication and coating process.